History

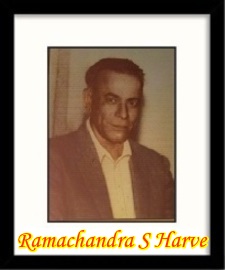

Our Founders

HARVE, the name of a tiny village near Mysuru, Karnataka, became a well-known and reputed name since 1940s as a result of pioneering enterprise of Late Ramachandra Subba Rao Harve. His endeavour of Make in India spirit saw realization in the companies, Pilot Engineering Works, Allied Engineering Works and Harve Electricals, which he set up in different parts of Mumbai. Harve, the brand trusted, carved a niche, in the emerging field of machine, electric motor and pump set manufacturing.

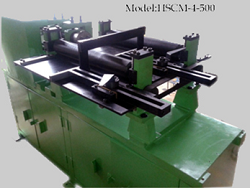

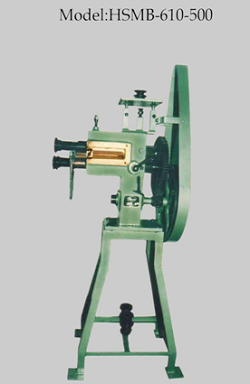

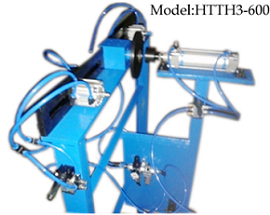

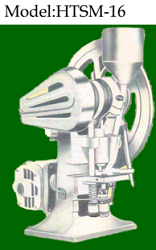

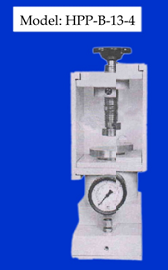

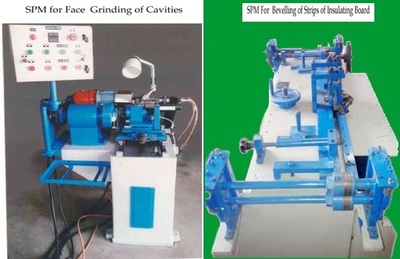

The mantle was carried forward by the next generation by increasing the product range and developing expertise in the manufacturing. Harve Wood working, Sheet metal, Metal cutting machines and Tableting machines were much sought after, by the respective industry.

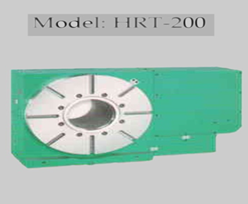

After division of activities in the family, late Ranjan Ramachandra Harve continued manufacturing some of the well-established machines in Harve Electricals, Goregaon (W), Mumbai. This manufacturing unit has been relocated at Mysuru, Karnataka and is established as Harve Engineering Company.

The promoters of Harve Engineering Company also engaged in manufacturing goods to reputed companies like M/S.Bharat Earth Movers Ltd.(BEML), Automotive Axles Ltd., J.K Tyres Ltd., Falcon Tyres Ltd., Brakes India Ltd., TVS Group, Wipro, Nestle(I) etc. The items ranged from simple machined parts to equipment and machines. This rich experience is reflected in the output of the company.